Crown center sp. z o. o.

CROWN CENTER is a private non-ferrous foundry with casting traditions since 1946.

Crown Center Company by many years of casting traditions, produces the highest quality of casting assortments well known in Europe and in all over the world.

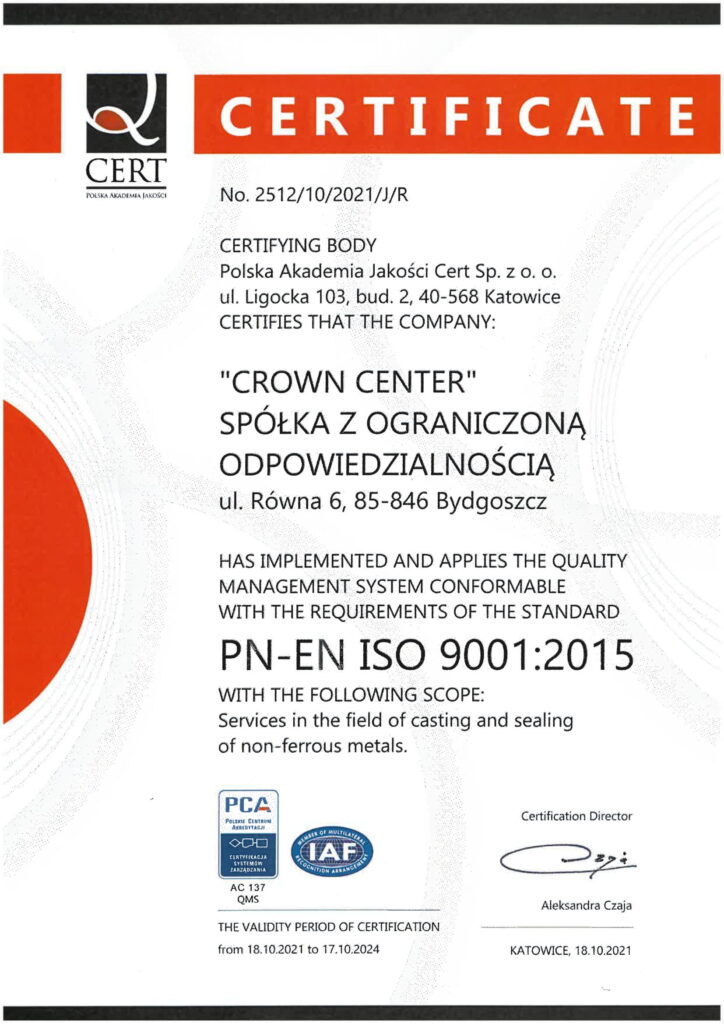

We are proud of our professional experience. It allows us to guarantee a high quality of our products and a good position on domestic market. We have got the considerable production possibilities in range of non-ferrous founding, mechanical treatment of the metallic elements and mechanical seal as well.

We export ca. 80% of our production to countries such as: Germany, Holland, France, Denmark, Austria, Sweden, Belgium, Ireland, England, Israel, Norway, Saudi Arabia, United Arab Emirates.

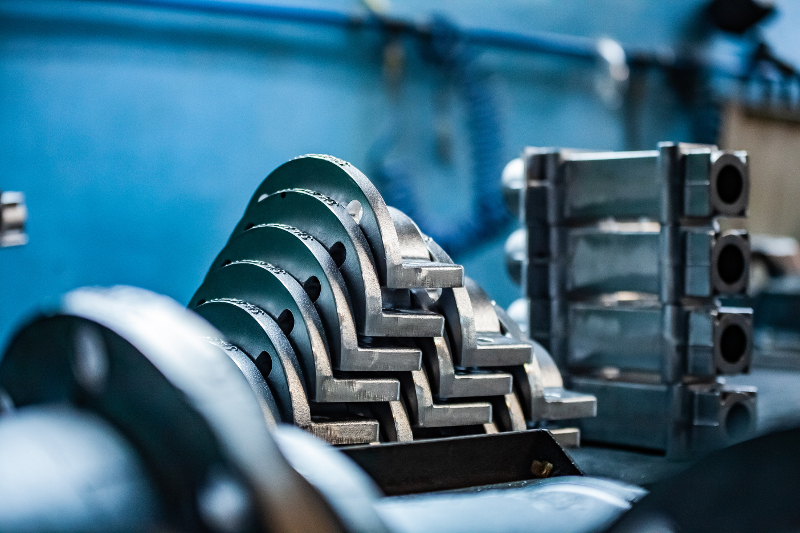

We make sand castings with aluminum and copper alloys making with sand form, chill mould and pressure casting die.

We have had a long time tradition in manufacturing of technique castings and old style lighting equipment.

We make seal of our castings with impregnation of „MALDANER” system – based on thermohardening resins, which guarantees sealing of casting microcracks for all sorts of castings.

We are flexible and open to different challenges.

In case of any question please contact us.